You’ve been googling metal roofing for three weeks. Every website tells you standing seam is “the best” but nobody explains why it costs twice as much as the metal panels you see on barns.

Your contractor quoted you $28,000 for your 2,000 square foot roof. Your neighbor paid $8,000 for “metal roofing” last year. You’re wondering if you’re getting ripped off or if your neighbor bought junk.

Here’s everything you need to know about standing seam metal roofs without the sales pitch or confusing technical terms that mean nothing to normal people.

What Is a Standing Seam Metal Roof?

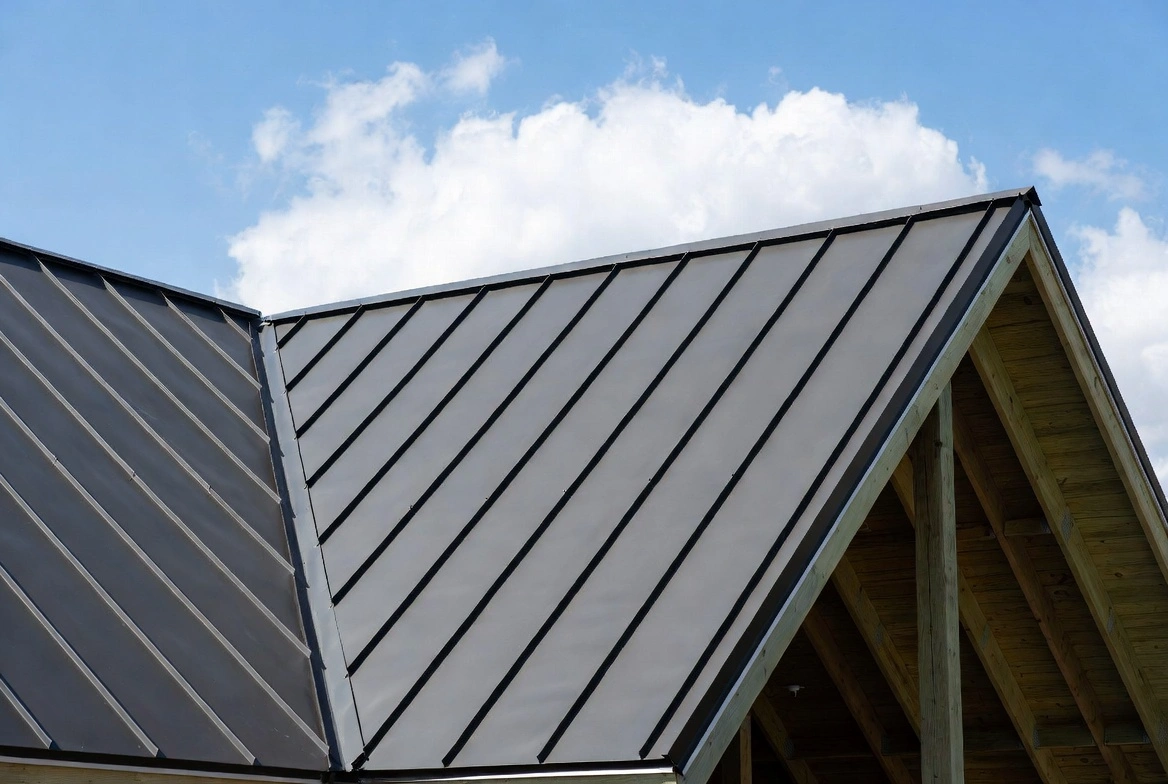

A standing seam metal roof uses vertical panels that lock together with raised seams and hidden fasteners.

Unlike exposed fastener systems like R-Panel or PBR panels where you see screws on the surface, standing seam hides everything underneath. The panels interlock, and clips beneath hold them to your roof deck.

The “standing seam” is the raised vertical rib where two panels meet—typically 1 to 2 inches tall running from your roof’s bottom edge to the peak.

This is what creates that clean, modern look you see on high-end homes, Tesla showrooms, and $800K barn renovations.

Key features:

- Panels run vertically from eave to ridge

- Hidden fastener system (concealed clips)

- Raised interlocking seams

- Panel widths: 12″, 16″, or 18″ (most common)

- Works on slopes as low as 1:12 (nearly flat)

- Available in steel, aluminum, copper, or zinc

There are two main installation types:

Snap-Lock Panels: Panels snap together by hand. Faster installation, lower labor cost, good for most residential projects.

Read related guide on Standing Seam Metal Roof Installation Cost: What Labor Actually Runs

Mechanical Seam: Panels are crimped together with a special seaming tool. Creates the most weather-tight seal. Required for commercial buildings and ultra-low slopes.

At Rainy Roofers, we install both systems. For typical homes with 3:12 pitch or steeper, snap-lock works great and saves you money. Flatter roofs or coastal high-wind areas? Mechanical seam is worth the extra cost.

Standing Seam Metal Roof Cost: What You’ll Actually Pay

Let’s talk numbers without the runaround.

Standing seam metal roofs cost $10-$16 per square foot installed for most residential projects using steel or aluminum.

For a 2,000 square foot roof, expect to pay $20,000-$32,000 total.

For a 1,500 square foot roof: $15,000-$24,000.

Why such a wide range?

Material choice affects everything:

- Steel: $10-$14 per square foot (most common)

- Aluminum: $11-$17 per square foot (better for coastal areas)

- Copper: $20-$40 per square foot (premium, lasts 100+ years)

- Zinc: $14-$20 per square foot (self-healing properties)

Your roof’s complexity changes the price:

Simple gable roof? You’re on the lower end. Multiple valleys, dormers, skylights, and a 12:12 pitch? Add 30-40% to the base cost.

Coating selection matters:

- Galvalume (unpainted): Cheapest, 25-year warranty

- SMP paint system: Mid-tier, 30-year warranty

- Kynar 500 (PVDF): Premium, 40-year warranty, best color retention

A client of mine went with the cheapest coating to save $1,200. Five years later, the paint was fading badly. He spent $4,500 on a roof coating to fix it.

Don’t make that mistake.

Labor typically runs $6-$14 per square foot depending on your location and roof complexity. This isn’t a DIY project unless you’re doing a small shed. The precision required, specialized tools, and safety issues make this a job for professionals.

Compare that to asphalt shingles at $5-$8 per square foot installed, but remember—shingles last 15-20 years. The standing seam lasts 40-70 years. Do the math on lifetime cost and metal wins easily.

Types of Standing Seam Systems

Not all standing seam is created equal.

Snap-Lock (Snap-Together):

Panels lock together by hand or with light pressure. No special tools required beyond basic fasteners.

- Faster installation = lower labor cost

- Minimum slope: typically 3:12

- Good for most residential applications

- Panels attached with pancake head screws through clips

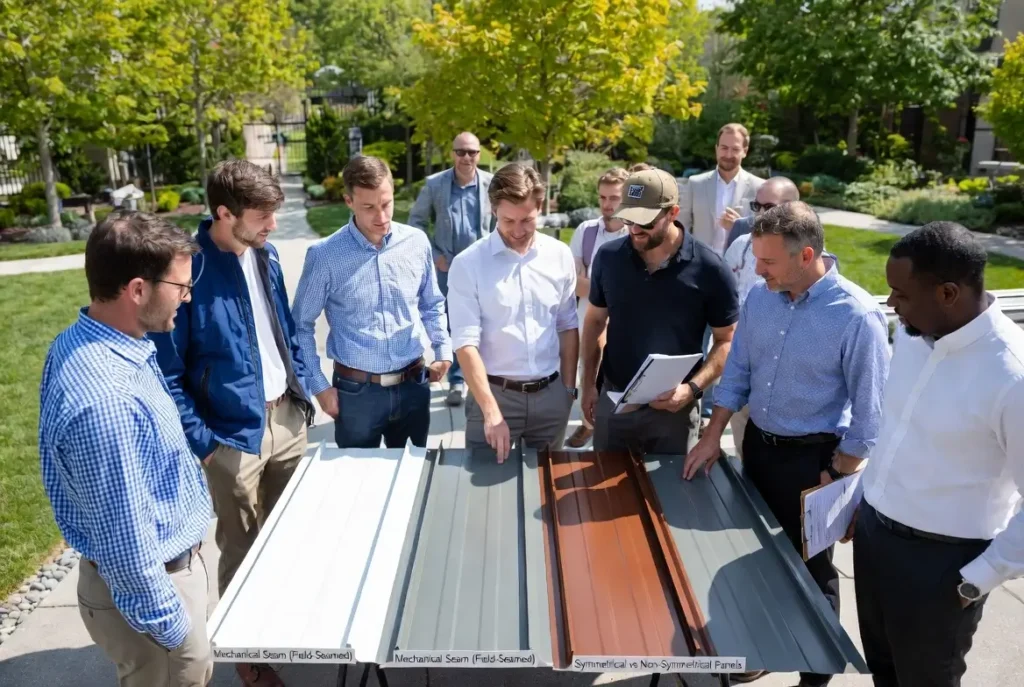

Mechanical Seam (Field-Seamed):

Panels are crimped together on-site using a mechanical seaming tool.

- Creates superior weather-tight seal

- Works on slopes as low as 1/4:12 or 1/2:12

- Required for commercial buildings

- Essential for coastal/high-wind areas

- 20-30% higher labor cost

Symmetrical vs Non-Symmetrical Panels:

Symmetrical systems let you replace individual panels after installation without tearing up the whole roof. Both legs of the seam are identical.

Non-symmetrical systems install progressively (left to right). If you need to replace a panel in the middle, you’re removing everything to the right of it first.

For residential projects, snap-lock makes sense 90% of the time. You save money, installation is faster, and performance is excellent for normal applications.

Go mechanical seams if you’re in Florida dealing with hurricanes, on the coast with salt air and wind-driven rain, or building commercials where longevity is critical.

Materials: Steel, Aluminum, Copper, or Zinc?

Steel (Most Common):

Galvalume-coated steel is the industry standard. It’s the sweet spot between cost and performance.

- Best bang for your buck

- 40-50 year lifespan with proper coating

- Handles wind, hail, and fire

- Can rust if coating is damaged

- 26 gauge standard (24 or 22 gauge for extreme weather)

Aluminum (Coastal Properties):

Lighter weight, naturally corrosion-resistant, perfect for saltwater environments.

- Won’t rust even if scratched

- 30% lighter than steel

- Softer metal (dents easier from hail)

- 10-20% more expensive than steel

- 50+ year lifespan

I’ve got a client on the coast with aluminum standing seam installed 12 years ago. Still looks perfect. His neighbor’s steel roof three blocks inland? Also perfect. But near salt water, aluminum is worth the premium.

Copper (Premium Choice):

The most expensive option, but it’s also the last roof you’ll ever install.

- 100+ year lifespan documented

- Develops green patina over time (some love it, some hate it)

- Softer than steel (better hail performance than you’d think)

- Very expensive: $20-$40 per square foot

- No painting required ever

Zinc (Self-Healing):

The interesting option most people don’t know about.

- Self-healing properties (minor scratches repair themselves)

- 100+ year lifespan

- Develops beautiful patina

- $14-$20 per square foot

- Requires expert installation

For 95% of homeowners, Galvalume steel with a quality PVDF coating is the right choice. You get excellent performance, 40+ year lifespan, and reasonable cost.

Go aluminum if you’re within 5 miles of saltwater. Go copper or zinc if you’re building a forever home and money isn’t the primary concern.

Standing Seam Metal Roof Colors

Standing seam comes in virtually any color you want.

Most popular colors:

- Charcoal Gray (most requested)

- Dove Gray (lighter, modern look)

- Black (dramatic, shows dirt less)

- White (maximum energy efficiency)

- Bronze/Brown earth tones

- Slate Gray (between charcoal and dove)

Dark colors make tall roofs look less imposing. Light colors make homes look larger and reduce cooling costs.

A white or light gray roof reflects 60-70% of solar heat. A dark gray or black roof absorbs most of it. In hot climates, light colors can cut cooling costs 10-25%.

The catch? Light colors show dirt, pollen, and streaking more than dark colors. Black and charcoal hide everything.

Your coating system affects how long colors last:

- PVDF (Kynar 500): Best fade resistance, 40-year warranty

- SMP coatings: Good fade resistance, 30-year warranty

- Standard polyester: Budget option, fades faster

Most manufacturers offer 30-100+ color options. Some even do custom colors if you’re willing to pay and meet minimum order quantities.

Installation: What Actually Happens

Standing seam installation is complex. Small mistakes create big problems.

The process:

- Tear-off old roofing (or install over existing if codes allow and deck is sound)

- Inspect and repair roof decking – any rotten boards must be replaced

- Install high-temperature underlayment – regular felt will melt under metal

- Install drip edge and starter strips

- Square the roof – critical step most DIYers skip

- Install first panel with precise alignment

- Lock subsequent panels together while maintaining alignment

- Install clips that secure panels but allow thermal expansion

- Install all trim – ridge cap, valleys, rake trim, wall flashings

- Final inspection for gaps, proper seaming, thermal movement accommodation

The thermal expansion piece is critical. Metal expands and contracts significantly with temperature changes. If clips are over-tightened or panels can’t move, you get warping, buckling, or “oil canning” (visible waviness).

This is why DIY standing seam rarely works on anything larger than a shed. The precision required, specialized tools (mechanical seamers cost $2,000-$5,000), and expertise needed make it a professional job.

Bad installation voids your warranty and creates leak points that won’t show up until year 3 when water damage is extensive.

Standing Seam vs Other Metal Roofing Systems

Standing Seam vs R-Panel / PBR Panel:

R-Panel metal roofing and PBR panels use exposed fasteners (screws visible on the surface).

- 40-50% cheaper than standing seam

- Faster installation

- Screws are potential leak points

- Maintenance required (screws loosen over time)

- 30-40 year lifespan vs 50-70 for standing seam

If budget is tight and you’re okay with exposed fasteners, PBR panels are a solid choice. They’re incredibly popular for commercial, agricultural, and modern residential projects.

The PBR panel vs R-Panel debate comes down to the purlin bearing leg design on PBR that creates better overlap. Both work, but PBR handles low slopes and weather better.

Standing Seam vs Asphalt Shingles:

- Shingles: $5-$8/sq ft, 15-20 year life, high maintenance

- Standing seam: $10-16/sq ft, 50+ year life, minimal maintenance

Over 50 years, you’re replacing shingles 2-3 times. Total cost: $15-$24/sq ft. Standing seam installed once: $10-16/sq ft.

The math favors metal if you’re staying in the house long-term.

Benefits That Actually Matter

Longevity: 50-70 years standard. Copper and zinc exceed 100 years. This is legitimately the last roof most homes will need.

Weather Performance:

- Class A fire rating (won’t ignite, won’t spread fire)

- Wind resistance up to 140+ mph (with proper installation)

- Hail resistant (Class 4 impact rating available)

- Snow slides off naturally

Energy Efficiency: Reflective coatings reduce cooling costs 10-25% in hot climates. The air gap between panels and deck adds insulation value.

Low Maintenance: No granules to wash away. No tabs to lift. No moss growth. Inspect every 5 years, clean gutters, done.

Resale Value: Appraisers recognize metal roofing adds value. Buyers love knowing the roof is solved for 50+ years.

Environmental: 100% recyclable. Most metal roofing contains 25-95% recycled content. When it finally comes off in 70 years, it goes back into production.

Common Problems to Avoid

Oil Canning: Visible waviness in flat panel areas. Not a structural issue but can look bad. Wider panels and lack of ribs make it worse. Choose striated panels or narrower widths to minimize.

Improper Fastening: Over-tightened clips prevent thermal movement. Panels buckle or warp. Under-tightened clips allow panels to lift in the wind.

Wrong Slope: Snap-lock on a 1:12 slope will leak. Mechanical seam required for low slopes. Know the minimum slope for your system.

Color Mismatch: Panels ordered at different times can have slight color variations (batch sensitivity). Order all panels at once or accept minor differences.

Condensation: Metal roofs can create condensation in poorly ventilated attics. Proper ventilation, insulation, and sometimes anti-condensation barriers solve this.

FAQs About Standing Seam Metal Roofs

How long does a standing seam metal roof last?

40-70 years typically, depending on material and coating. Steel with PVDF coating: 50+ years. Aluminum: 50+ years. Copper and zinc: 100+ years documented.

Can I install a standing seam metal roof myself?

Not recommended unless you’re doing a small shed. Requires specialized tools (mechanical seamers cost $2,000+), precision installation, and proper safety equipment. Mistakes void warranties and create expensive leak problems. Call Rainy Roofers.

What is the minimum slope for standing seam?

Snap-lock systems: 3:12 minimum. Mechanical seam systems: as low as 1/4:12 or 1/2:12 depending on manufacturer specs. Always follow manufacturer guidelines or you’ll void the warranty.

Do standing seam metal roofs leak?

Not when installed correctly. The concealed fastener system eliminates screw penetration leak points. Leaks typically come from improper flashing at valleys, chimneys, or transitions—installation errors, not system failure.

Is standing seam worth the extra cost over exposed fastener panels?

If you’re planning to own the building 20+ years, yes. The longevity, lower maintenance, and lack of screw-related issues justify the 40-50% cost premium. For short-term ownership or budget-constrained projects, PBR panels or R-Panel metal roofing are solid alternatives.

What colors are available?

30-100+ colors depending on manufacturer. Most popular: charcoal gray, black, white, bronze, slate gray. Light colors reduce cooling costs. Dark colors hide dirt better.

Can standing seam go over existing shingles?

Sometimes, if local codes allow and your deck is structurally sound. Saves tear-off costs ($1-2 per square foot). Requires inspection to verify no rot or damage underneath. Not all jurisdictions permit this.

How much does standing seam cost?

$10-16 per square foot installed for steel or aluminum. $20-40 per square foot for copper. For a 2,000 sq ft roof: $20,000-$32,000 typically.

The Real Decision Point

Here’s what matters.

Standing seam metal roofing costs more upfront than almost any other residential roofing option. You’ll pay 2-3x more than asphalt shingles and 40-50% more than exposed fastener metal panels.

But it’s also the last roof your building will need for 50-70 years. No re-roofing. No constant maintenance. No leak repairs every few years.

The people who regret standing seam are those who didn’t plan to stay in the house long-term. You pay the premium, someone else gets the benefit.

The people who love standing seam are those who own the building for 20+ years. The initial investment pays for itself through longevity, energy savings, and zero maintenance headaches.

At Rainy Roofers, we’re transparent about when a standing seam makes sense and when it doesn’t. If you’re flipping a house, R-Panel or PBR panels are better value. If you’re building your retirement home, standing seam is the smart long-term play.

Don’t choose based on what your neighbor installed or what looks coolest on Pinterest. Choose based on your actual situation: how long you’ll own the building, your budget, and what matters most—lowest upfront cost or lowest lifetime cost.

Your roof is one of the most expensive parts of your home. Get it right the first time.